采用中间轴设计,适用于超长轴间距动力传动场合。

| 规格 | DA | D1 | D2 | D3 | d1(max) | L1 | LT | F(LS)设计计算按457.2(18") | 许用转速(max) | 公称转矩 | 瞬时转矩(max) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLAT95-6 | 132 | 84 | 95 | 56 | 60 | 70 | =LS-46 | 按设计需求给出数据 | 28900 | 1000 | 1300 |

| RLAT125-6 | 158 | 105 | 125 | 72 | 75 | 90 | =LS-55 | 24200 | 2300 | 3000 | |

| RLAT145-6 | 182 | 133 | 145 | 87 | 95 | 110 | =LS-65 | 21000 | 4000 | 5000 | |

| RLAT175-6 | 220 | 161 | 175 | 109 | 115 | 135 | =LS-77 | 17400 | 6700 | 8500 | |

| RLAT205-6 | 249 | 189 | 205 | 125 | 135 | 150 | =LS-83 | 15300 | 10500 | 13000 | |

| RLAT220-6 | 266 | 210 | 220 | 140 | 150 | 175 | =LS-95 | 14400 | 14500 | 18500 | |

| RLAT250-6 | 295 | 231 | 250 | 162 | 165 | 200 | =LS-112 | 12900 | 21000 | 27000 | |

| RLAT270-6 | 328 | 252 | 270 | 171 | 180 | 210 | =LS-119 | 11600 | 26500 | 35000 | |

| RLAT295-6 | 355 | 280 | 295 | 187 | 200 | 230 | =LS-131 | 10800 | 35000 | 45500 | |

| RLAT320-6 | 382 | 301 | 320 | 201 | 215 | 250 | =LS-138 | 10000 | 41000 | 52000 | |

| 规格 | 质点G | 角向偏差 | 轴向偏差(max) | L2 | 中间质量m | 中间转动惯量 | 中间扭转刚度 | 联轴器质量M | 扭转刚度 | 转动惯量 | 总质量(KG) |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m²) | ||

| RLAT95-6 | 66 | 0.35 | 1.6 | - | 3.92 | 2.76 | 28.2 | 8.4 | 0.05 | 0.014 | (3.92/1000)*(Ls-457.2)+8.4 |

| RLAT125-6 | 81 | 2 | - | 5.91 | 6.95 | 70.9 | 14.4 | 0.118 | 0.036 | (5.91/1000)*(Ls-457.2)+14.4 | |

| RLAT145-6 | 93.5 | 2.4 | - | 8.19 | 14.1 | 144 | 23.6 | 0.229 | 0.084 | (8.19/1000)*(Ls-457.2)+23.6 | |

| RLAT175-6 | 111 | 3 | - | 11.6 | 31.7 | 323 | 40.12 | 0.468 | 0.216 | (11.6/1000)*(Ls-457.2)+40.12 | |

| RLAT205-6 | 121.5 | 3.8 | - | 16.2 | 58 | 591 | 59 | 0.806 | 0.416 | (16.2/1000)*(Ls-457.2)+59 | |

| RLAT220-6 | 137 | 4 | - | 19.8 | 89.2 | 909 | 79.2 | 1.17 | 0.671 | (19.8/1000)*(Ls-457.2)+79.2 | |

| RLAT250-6 | 155.5 | 4.6 | - | 23.1 | 141 | 1433 | 107 | 1.76 | 1.13 | (23.1/1000)*(Ls-457.2)+107 | |

| RLAT270-6 | 166 | 5 | - | 28.3 | 191 | 1944 | 140 | 2.34 | 1.789 | (28.3/1000)*(Ls-457.2)+140 | |

| RLAT295-6 | 179 | 5.6 | - | 35.3 | 283 | 2889 | 182 | 3.25 | 2.8 | (35.3/1000)*(Ls-457.2)+182 | |

| RLAT320-6 | 191.5 | 5.8 | - | 38.1 | 355 | 3620 | 224 | 4.09 | 4.01 | (38.1/1000)*(Ls-457.2)+224 | |

| 规格 | D | D1 | D2 | D3 | d1(max) | L1 | LT | F(LS)设计计算按457.2(18") | 许用转速(max) | 公称转矩 | 瞬时转矩(max) |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLAT145-8 | 182 | 133 | 145 | 87 | 95 | 110 | =LS-65 | 按设计需求给出数据 | 21000 | 5700 | 7400 |

| RLAT175-8 | 220 | 161 | 175 | 109 | 115 | 135 | =LS-77 | 17400 | 9600 | 12300 | |

| RLAT205-8 | 249 | 189 | 205 | 125 | 135 | 150 | =LS-83 | 15300 | 15000 | 19000 | |

| RLAT220-8 | 266 | 210 | 220 | 140 | 150 | 175 | =LS-95 | 14400 | 20000 | 26500 | |

| RLAT250-8 | 295 | 231 | 250 | 162 | 165 | 200 | =LS-112 | 12900 | 29200 | 38200 | |

| RLAT270-8 | 328 | 252 | 270 | 171 | 180 | 210 | =LS-119 | 11600 | 38100 | 49000 | |

| RLAT295-8 | 355 | 280 | 295 | 187 | 200 | 230 | =LS-131 | 10800 | 49500 | 64000 | |

| RLAT320-8 | 382 | 301 | 320 | 201 | 215 | 250 | =LS-138 | 10000 | 59000 | 77000 | |

| RLAT350-8 | 410 | 322 | 350 | 218 | 230 | 270 | =LS-148 | 9300 | 81000 | 105000 | |

| RLAT390-8 | 462 | 364 | 390 | 248 | 260 | 310 | =LS-169 | 8300 | 115000 | 150000 | |

| RLAT435-8 | 510 | 413 | 435 | 280 | 295 | 340 | =LS-191 | 7500 | 168500 | 220000 | |

| RLAT498-8 | 580 | 469 | 498 | 324 | 335 | 390 | =LS-213 | 6600 | 250000 | 320000 | |

| RLAT545-8 | 625 | 511 | 545 | 355 | 365 | 425 | =LS-233 | 6100 | 330000 | 420000 | |

| RLAT595-8 | 680 | 553 | 595 | 387 | 395 | 460 | =LS-248 | 5600 | 410000 | 540000 | |

| 规格 | 质点G | 角向偏差 | 轴向偏差(max) | L2 | 中间质量m | 中间转动惯量 | 中间扭转刚度 | 联轴器质量M | 扭转刚度 | 转动惯量 | 总质量(KG) |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m²) | ||

| RLAT145-8 | 94 | 0.25 | 1.6 | - | 8.19 | 14.1 | 144 | 23.9 | 0.273 | 0.085 | (8.19/1000)*(LS-457.2)+23.9 |

| RLAT175-8 | 111.5 | 1.8 | - | 11.6 | 31.7 | 323 | 40.5 | 0.578 | 0.216 | (11.6/1000)*(LS-457.2)+40.5 | |

| RLAT205-8 | 122 | 2.4 | - | 16.2 | 58 | 591 | 59.4 | 1.019 | 0.42 | (16.2/1000)*(LS-457.2)+59.4 | |

| RLAT220-8 | 138 | 2.6 | - | 19.8 | 89.2 | 909 | 80 | 1.51 | 0.678 | (19.8/1000)*(LS-457.2)+80 | |

| RLAT250-8 | 156.5 | 3 | - | 23.1 | 141 | 1433 | 108 | 2.33 | 1.14 | (23.1/1000)*(LS-457.2)+108 | |

| RLAT270-8 | 166.5 | 3.2 | - | 28.3 | 191 | 1944 | 141 | 3.12 | 1.8 | (28.3/1000)*(LS-457.2)+141 | |

| RLAT295-8 | 180 | 2.6 | - | 36.3 | 283 | 2889 | 184 | 4.44 | 2.83 | (36.3/1000)*(LS-457.2)+184 | |

| RLAT320-8 | 193 | 3.8 | - | 38.1 | 365 | 3620 | 227 | 5.61 | 4.06 | (38.1/1000)*(LS-457.2)+227 | |

| RLAT350-8 | 69 | 3.8 | - | 48.8 | 532 | 5422 | 283 | 7.98 | 5.82 | (48.8/1000)*(LS-457.2)+283 | |

| RLAT390-8 | 78.5 | 4.4 | - | 58.7 | 833 | 8485 | 406 | 12.2 | 10.7 | (58.7/1000)*(LS-457.2)+406 | |

| RLAT435-8 | 88 | 5 | - | 79.3 | 1427 | 14542 | 566 | 19.7 | 18.9 | (79.3/1000)*(LS-457.2)+566 | |

| RLAT498-8 | 99 | 5.8 | - | 99.7 | 2415 | 24613 | 828 | 32 | 36 | (99.7/1000)*(LS-457.2)+828 | |

| RLAT545-8 | 109 | 6.4 | - | 122 | 3536 | 36032 | 1055 | 43.7 | 54.2 | (122/1000)*(LS-457.2)+1055 | |

| RLAT595-8 | 116.5 | 7.2 | - | 138 | 4769 | 48597 | 1331 | 58.5 | 80.5 | (138/1000)*(LS-457.2)+1331 | |

| 规格 | D | D1 | D2 | D3 | d1(max) | L1 | LT | F(LS)设计计算按457.2(18") | 许用转速(max) | 公称转矩 | 瞬时转矩(max) |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLAT220-10 | 266 | 210 | 220 | 140 | 150 | 175 | =LS-95 | 按设计需求给出数据 | 14400 | 26800 | 34800 |

| RLAT250-10 | 295 | 231 | 250 | 162 | 165 | 200 | =LS-112 | 12900 | 38300 | 49800 | |

| RLAT270-10 | 328 | 252 | 270 | 171 | 180 | 210 | =LS-119 | 11600 | 49400 | 64200 | |

| RLAT295-10 | 355 | 280 | 295 | 187 | 200 | 230 | =LS-131 | 10800 | 64000 | 83200 | |

| RLAT320-10 | 382 | 301 | 320 | 201 | 215 | 250 | =LS-138 | 10000 | 76500 | 99500 | |

| RLAT350-10 | 410 | 322 | 350 | 218 | 230 | 270 | =LS-148 | 9300 | 105100 | 136600 | |

| RLAT390-10 | 462 | 364 | 390 | 248 | 260 | 310 | =LS-169 | 8300 | 151800 | 197300 | |

| RLAT435-10 | 510 | 413 | 435 | 280 | 295 | 340 | =LS-191 | 7500 | 219600 | 285500 | |

| RLAT498-10 | 580 | 469 | 498 | 324 | 335 | 390 | =LS-213 | 6600 | 321800 | 422200 | |

| RLAT545-10 | 625 | 511 | 545 | 355 | 365 | 425 | =LS-233 | 6100 | 430000 | 559000 | |

| RLAT595-10 | 680 | 553 | 595 | 387 | 395 | 460 | =LS-248 | 5600 | 535000 | 695500 | |

| 规格 | 质点G | 角向偏差 | 轴向偏差(max) | L2 | 中间质量m | 中间转动惯量 | 中间扭转刚度 | 联轴器质量M | 扭转刚度 | 转动惯量 | 总质量(KG) |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Cts-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m²) | ||

| RLAT220-10 | 139 | 0.15 | 1.6 | - | 19.8 | 89.2 | 909 | 80.6 | 1.31 | 0.648 | (19.8/1000)*(LS-457.2)+80.6 |

| RLAT250-10 | 157.5 | 2 | - | 23.1 | 141 | 1433 | 109 | 2.02 | 1.15 | (23.1/1000)*(LS-457.2)+109 | |

| RLAT270-10 | 167.5 | 2.1 | - | 28.3 | 191 | 1944 | 142 | 2.73 | 1.82 | (28.3/1000)*(LS-457.2)+142 | |

| RLAT295-10 | 191 | 2.4 | - | 35.5 | 283 | 2889 | 186 | 3.77 | 2.86 | (35.5/1000)*(LS-457.2)+186 | |

| RLAT320-10 | 194 | 2.4 | - | 38.1 | 353 | 3620 | 229 | 4.71 | 4.11 | (38.1/1000)*(LS-457.2)+229 | |

| RLAT350-10 | 211 | 2.4 | - | 48.8 | 532 | 5422 | 286 | 6.78 | 5.88 | (48.8/1000)*(LS-457.2)+286 | |

| RLAT390-10 | 239 | 2.8 | - | 58.7 | 833 | 8485 | 409 | 10.2 | 10.8 | (58.7/1000)*(LS-457.2)+409 | |

| RLAT435-10 | 262 | 3.2 | - | 79.3 | 1427 | 14542 | 572 | 15.8 | 19.1 | (79.3/1000)*(LS-457.2)+572 | |

| RLAT498-10 | 297.5 | 3.8 | - | 99.7 | 2415 | 24613 | 836 | 24.7 | 36.4 | (99.7/1000)*(LS-457.2)+836 | |

| RLAT545-10 | 322 | 4 | - | 122 | 3536 | 36032 | 1065 | 33.8 | 54.7 | (122/1000)*(LS-457.2)+1065 | |

| RLAT595-10 | 346.5 | 4.6 | - | 138 | 4769 | 48597 | 1342 | 43.5 | 81.2 | (138/1000)*(LS-457.2)+1342 |

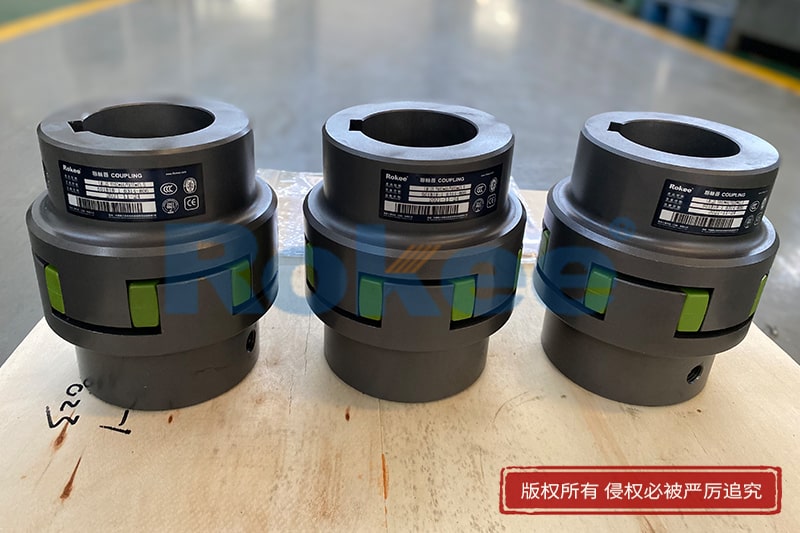

RLAT型膜片联轴器为RLAD的衍生型号,适用于超长距离的扭矩传递。

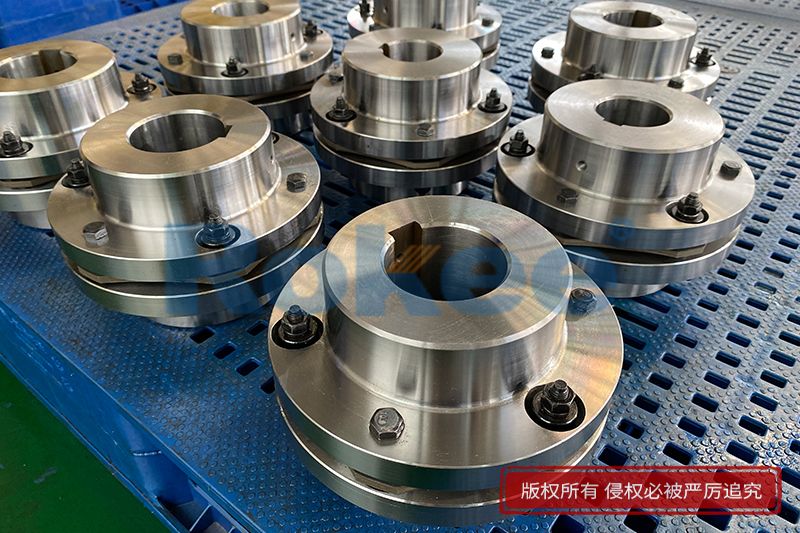

孔径,外圆尺寸,轴套长度等均可另行设计。

由于长轴设计牵涉到转速,附加弯矩,等均有关系变化, 因此在传动系统设计之初与Rokee工程师联系, 尽早介入可行设计达到良好效果。

超长轴距膜片联轴器,中间轴膜片联轴器

《RLAT超长轴距膜片联轴器》发布于2022年7月20日